Enhance your operations with advanced Real-Time Data and Lean Manufacturing

Optimize your operations and boost productivity through data-driven insights and lean manufacturing principles, supported by our team of production and operation specialists.

Why Digitalize?

Don't settle for inefficient manufacturing processes

As a company director, you're always looking for ways to optimize your operations and stay ahead of the competition.

Identify Bottlenecks

By utilizing cutting-edge real-time data and lean manufacturing strategies, you can streamline your production process and improve efficiency.

Our solutions are designed to provide you with data-driven insights and lean manufacturing concepts that will help you identify bottlenecks, reduce waste, and increase overall productivity.

Reduce Waste

From machine sensors to advanced analytics and customizable dashboards, our tools are tailored to your needs and offer unmatched visibility into your operations.

Our team of experts understand the intricacies of production processes and can guide you through the implementation of lean manufacturing strategies, minimizing inventory, and reducing costs, all while maintaining the highest levels of quality.

Increase Overall Productivity

Don't settle for inefficient manufacturing processes - partner with us to streamline your operations and optimize your production process.

Contact us today to learn how our real-time data and lean manufacturing strategies can help take your business to the next level.

Turning Machine Data into Actionable Production Information

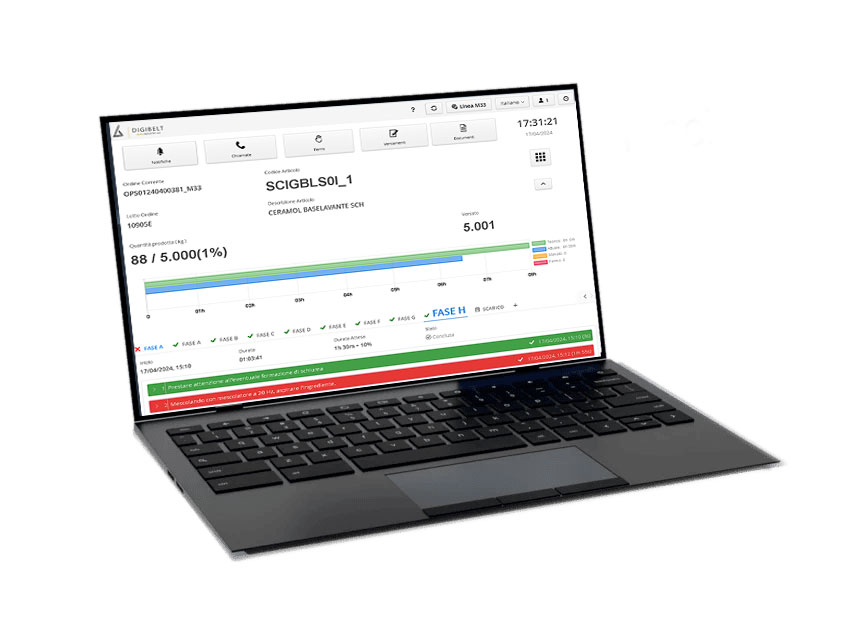

FACTORYAL XLayer data-collection platform transforms raw machine data into meaningful production information. With the Factory Modeler tool, users can independently define how this transformation occurs. By leveraging the ISA-95 standard, data is linked to specific machines, shop-floor areas and departments, building a comprehensive factory model that can be utilized by production control systems such as MES (Manufacturing Execution Systems).

A comprehensive solution on-premises or in the cloud

With the integration of Digibelt modules into the X Platform, it is possible to derive value from data and enable a continuous improvement process. Digibelt offers a digital transformation pathway for processes and enhances factory efficiency through Lean principles, available both on-premises and in the cloud via CORVINA.

Our Own Factory

Learn how EXOR International tackled the steps towards smart manufacturing